Linear Odo

Revolutionary odometry tracking system using linear rail mechanics to eliminate wheel slippage and dramatically improve autonomous navigation precision for FTC robotics.

Gallery

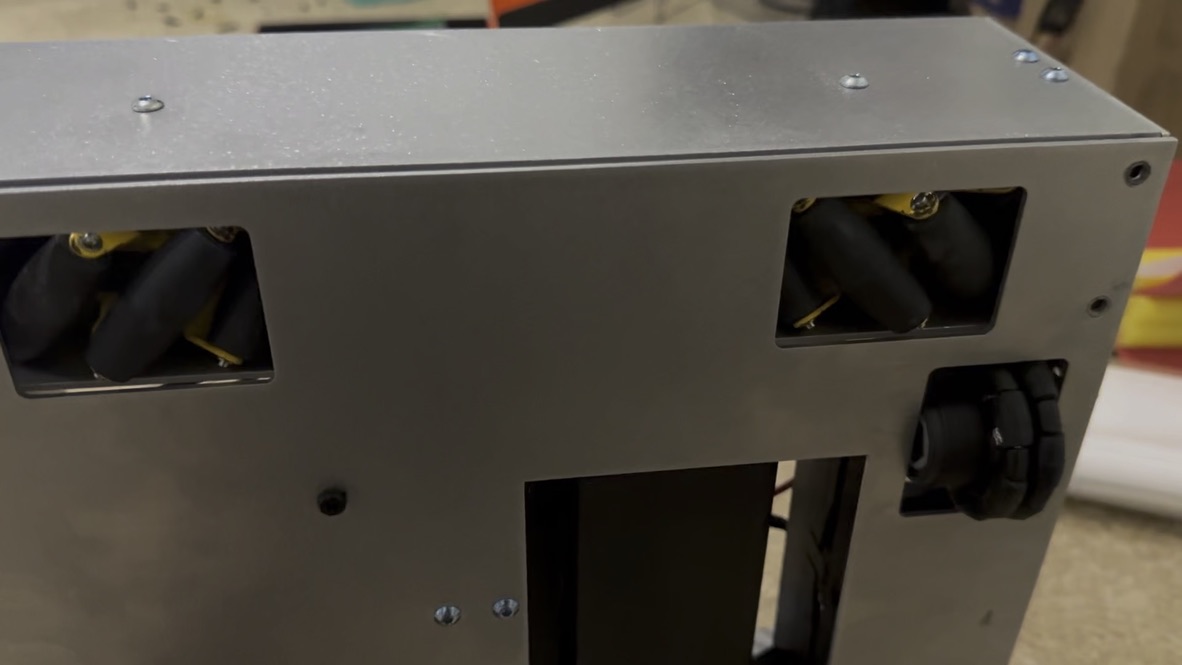

Final Integrated Example

How my team used this odometer

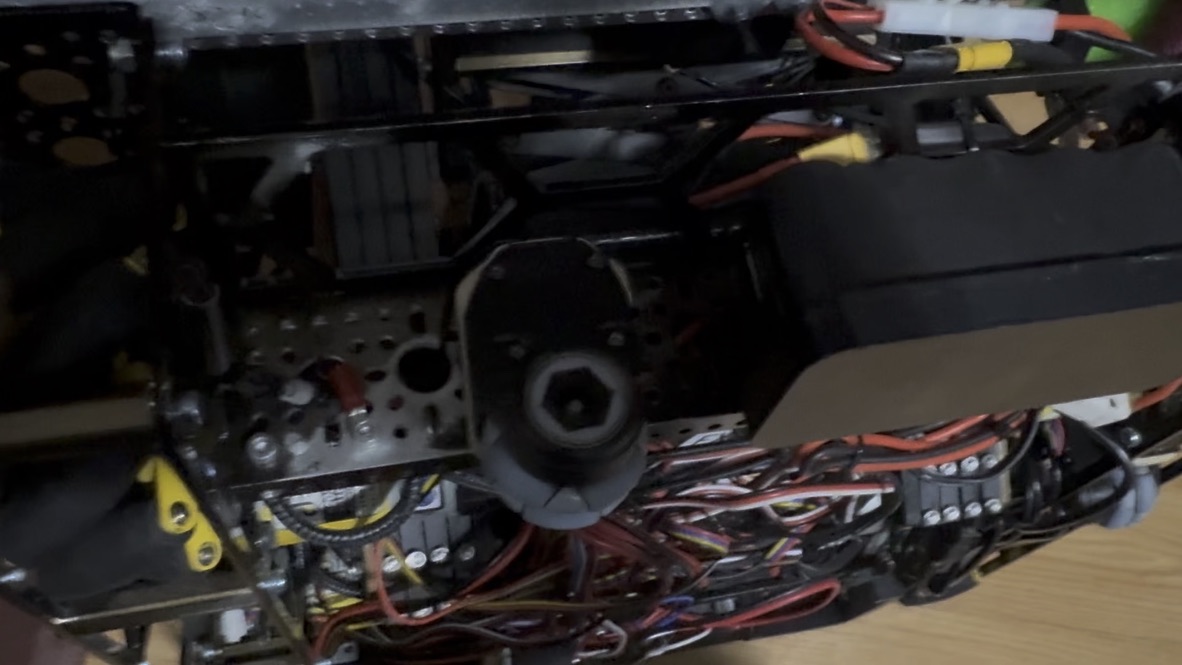

Linear Motion Showcase

Example of how it works

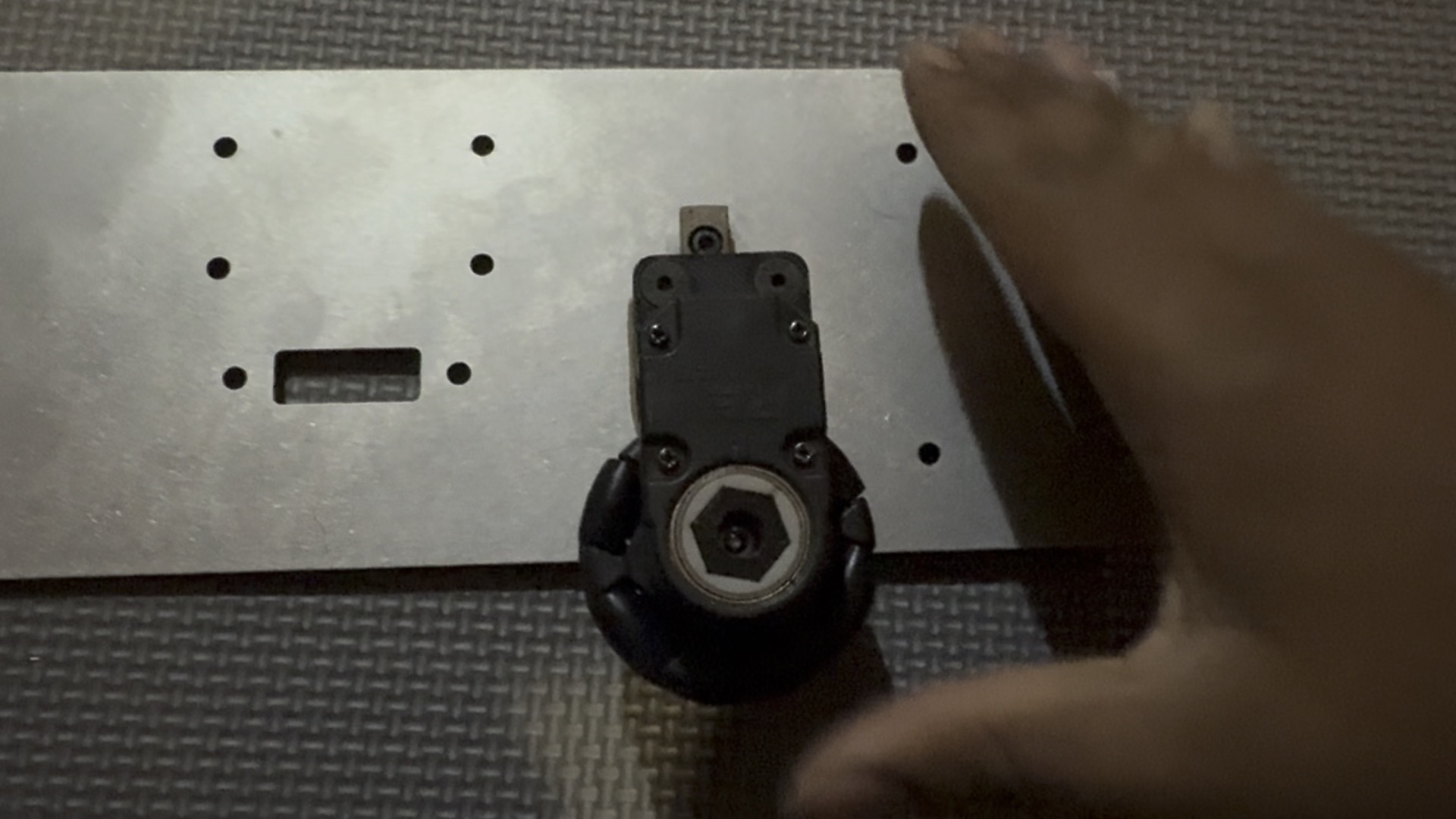

Early Prototype

An early version used on an old robot for testing

The Problem

Traditional FTC odometry systems rely on omni-wheels or tracking wheels that maintain contact with the field through spring tension or dead weight. This approach introduces several critical limitations:

- Wheel slippage during rapid acceleration or direction changes

- Inconsistent contact pressure leading to variable tracking accuracy

- Drift accumulation over long autonomous periods

- Field surface dependency affecting reliability across different venues

Teams experienced drift errors of 6-12 inches during typical 30-second autonomous periods, making precise navigation nearly impossible for complex multi-element routines.

Innovation: Linear Rail Mechanics

The Linear Odo system eliminates radial-based tracking entirely, instead using precision linear rails that physically constrain movement to exact geometric relationships.

Core Principle

the radial movement of traditional odometers can cause slight drifts and loss of contact with the floor:

- Precision Linear rails: Industrial-grade components with

<0.001"play that are affordable - Magnetic Encoders: Direct position feedback without mechanical slip

- Rigid Steel Frame: Eliminates compliance-based tracking errors

Technical Implementation

The mechanism consists of:

- Primary Rails: 55mm linear rails with precision ball bearings

- Encoder Mount: custom 3d printed enclosure with magnet directly attached on the wheel

- Contact System: Spring-loaded contact points maintaining field reference

- Data Processing: Real-time position fusion with IMU data through pinpoint and other libraries

Software Integration

The system integrates with existing FTC control systems through:

TODO

Testing & Validation

Precision Testing

Controlled tests measured system accuracy across various scenarios:

- Straight Path: 3-5x better

- Simple Shape Path(Square): 5-7x better

- Complex Path(Spline Curve): 3-4x better

Real-World Performance

Season-long data from implementing teams showed:

- Autonomous Success Rate: tracking rarely became the cause of major problems

- Precision Movements: Sub-inch accuracy maintained

- Reliability: Zero mechanical failures across 100+ matches

- Servicablity: All in one module which makes it very easy to replace

Engineering Challenges & Solutions

Challenge 1: Field Interaction

Problem: Maintaining consistent contact with varying field surfaces without having too much force that binding occurs Solution: Rubber bands instead of springs to infinetly adjust the tension in the system

Challenge 2: Dynamic Loading

Problem: Buckling on strafes or moving while turning Solution: Switched from community standard omni wheel to new cheaper and better option

Challenge 3: Manufacturing Precision

Problem: Achieving required tolerances with FTC fabrication capabilities Solution: Referenced sensor manufacturers casing to ensure a perfect fit and proper tracking

Challenge 4: Integration Complexity

Problem: Adding precision system without overwhelming teams Solution: Works with the most used sensor and the most used localization libraries

Lessons Learned

Design Philosophy

- Precision vs Complexity: Advanced systems require proportional documentation

- Manufacturing Reality: Theoretical performance must meet practical fabrication

- Team Capability: Solutions must match team skill and resource levels

- Iterative Development: Complex systems benefit from continued updates and revisions

Technical Insights

- Linear systems excel in applications requiring absolute precision

- Mechanical constraints often outperform algorithmic corrections

- Field-relative measurements provide more stable references than robot-relative

- Integration complexity can limit adoption despite performance benefits

Linear Odo demonstrates that breakthrough performance improvements often require fundamental reconsideration of accepted approaches, and that precision engineering principles can be successfully adapted to competitive robotics environments.