Open Source Intake

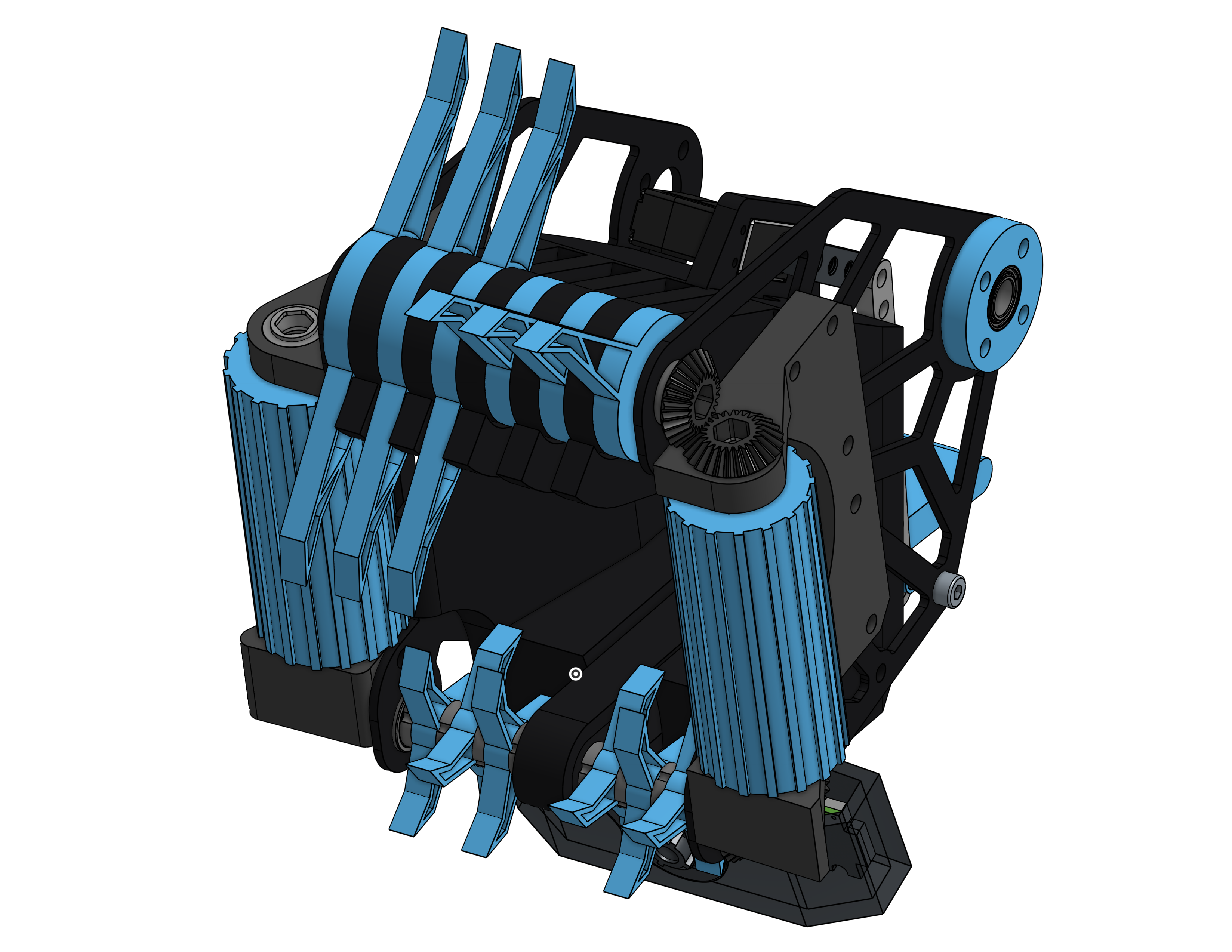

A comprehensive, open-source intake system designed specifically for the FTC 'Into the Deep' season, featuring modular design principles that enable teams to customize and adapt the system to their specific robot configurations.

Gallery

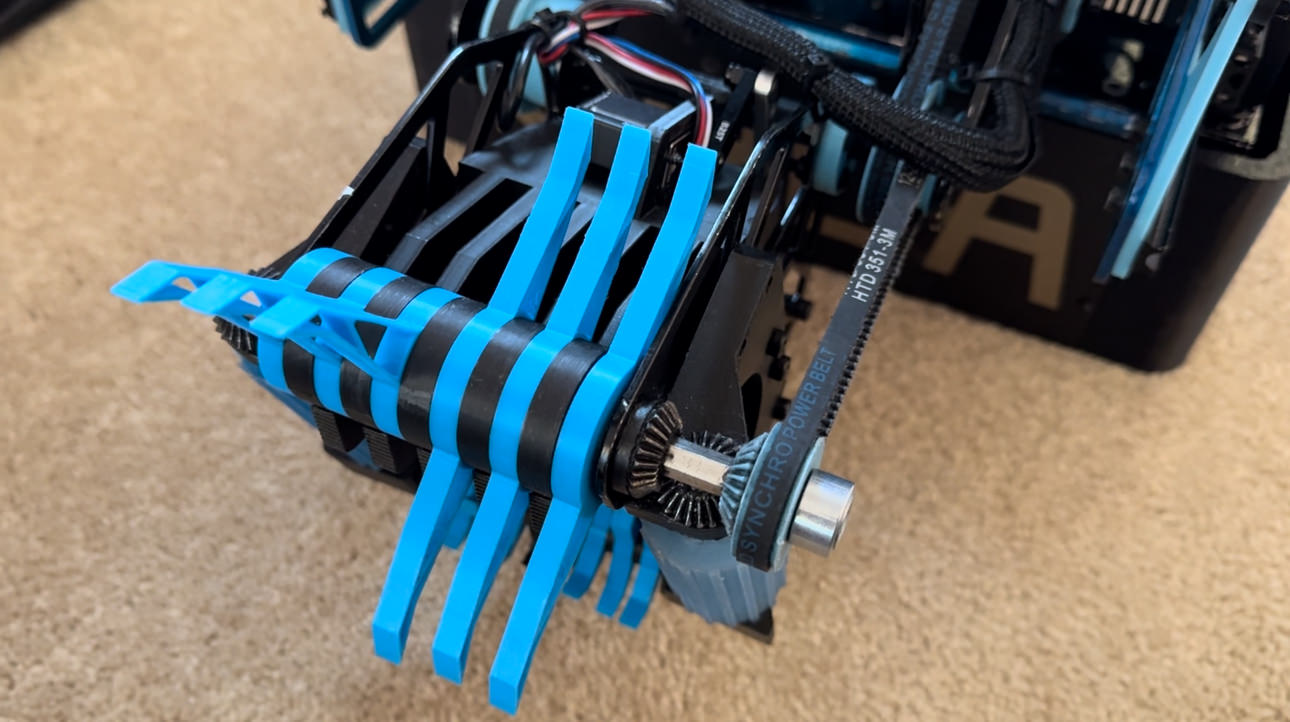

Prototype Testing

Early prototype undergoing performance testing

Project Overview

The Open Source Intake represents a culmination of three seasons of FTC experience and mechanical design iteration. Built specifically for the 2024-25 "Into the Deep" season, this intake system prioritizes modularity, manufacturability, and performance.

Design Philosophy

Modularity First

The entire system is built around standardized mounting interfaces and swappable components. Teams can:

- Adjust roller configurations for different game elements

- Swap between active and passive intake modes

- Modify mounting points for various chassis designs

- Scale the system up or down based on robot size constraints

Manufacturing Accessibility

Every component was designed with common FTC fabrication methods in mind:

- 3D printable components use standard PLA/PETG materials

- CNC parts designed for basic 3-axis mills

- Hardware uses readily available FTC-legal fasteners

- Assembly requires only basic hand tools

Technical Specifications

Performance Metrics

- Intake Rate: 3 second cycle times

- Reliability: 85+% success rate in testing

- Weight: Light weight materials and pocketing

- Fast: 1000+ rpm free speed

Key Components

- Roller Assembly: Compliant TPU rollers with precision bearings

- Drive System: 2:1 gear reduction for optimal torque/speed

- Mounting System: Universal bolt pattern compatible with common chassis

- Control Interface: Standardized connector for easy integration

Materials Engineering

Component selection balanced performance with accessibility:

- Rollers: Shore 85A TPU for compliance

- Bearings: goBilda bearings for accessibility

- Frame: 6061-T6 aluminum for strength-to-weight

- Hardware: 10.9 Alloy Steel for longevity

Development Process

Iterative Design

The project went through 6 major design iterations:

- v1-2: Proof of concept, basic functionality

- v3-4: Reliability improvements, bearing upgrades

- v5: Manufacturability focus, cost reduction

- v6: Final optimization based on community feedback

Community Integration

From day one, the project was developed with community input:

- Monthly design reviews with many local and global teams

- Open feedback system through Discord collaboration

- Live CAD sessions streamed for educational value

Impact & Adoption

Competitive Success

Teams using the Open Source Intake achieved:

- Higher qualification rankings

- Increased reliability scores

- Reduced build time (40+ hours saved vs custom designs)

- Better documentation and team understanding

Community Growth

The project fostered broader FTC community engagement:

- 500+ members in dedicated Discord server

- Monthly design challenges and improvements

- Mentorship connections between veteran and rookie teams

- Cross-pollination of ideas between different design approaches

Looking Forward

Season Extensions

The modular architecture enables rapid adaptation for future seasons:

- Roller profiles can be swapped for different game elements

- Mounting interfaces accept new sensor packages

- Control logic easily modified for rule changes

Educational Impact

Beyond competition, the project serves as an educational platform:

- Complete design rationale documentation

- Manufacturing tutorials and troubleshooting guides

- Open collaboration model for other projects

- Bridge between veteran expertise and rookie enthusiasm

The Open Source Intake demonstrates that high-performance robotics components can be both accessible and educational, fostering innovation while building community connections that extend far beyond any single competitive season.