Open-Source Swerve Drive

Early-stage open-source swerve drive project exploring 3D-printed robotics locomotion through affordable components and iterative design.

Gallery

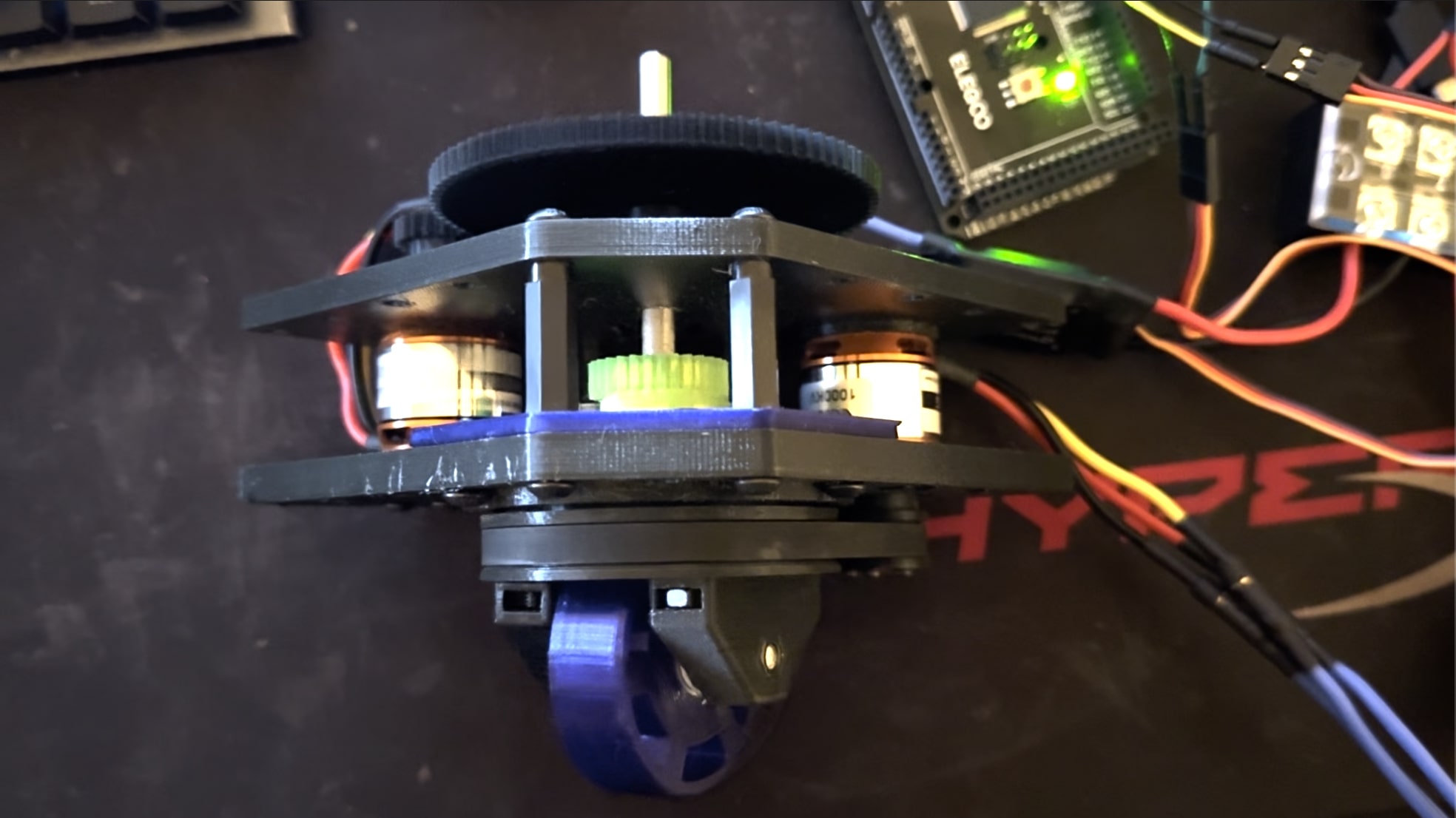

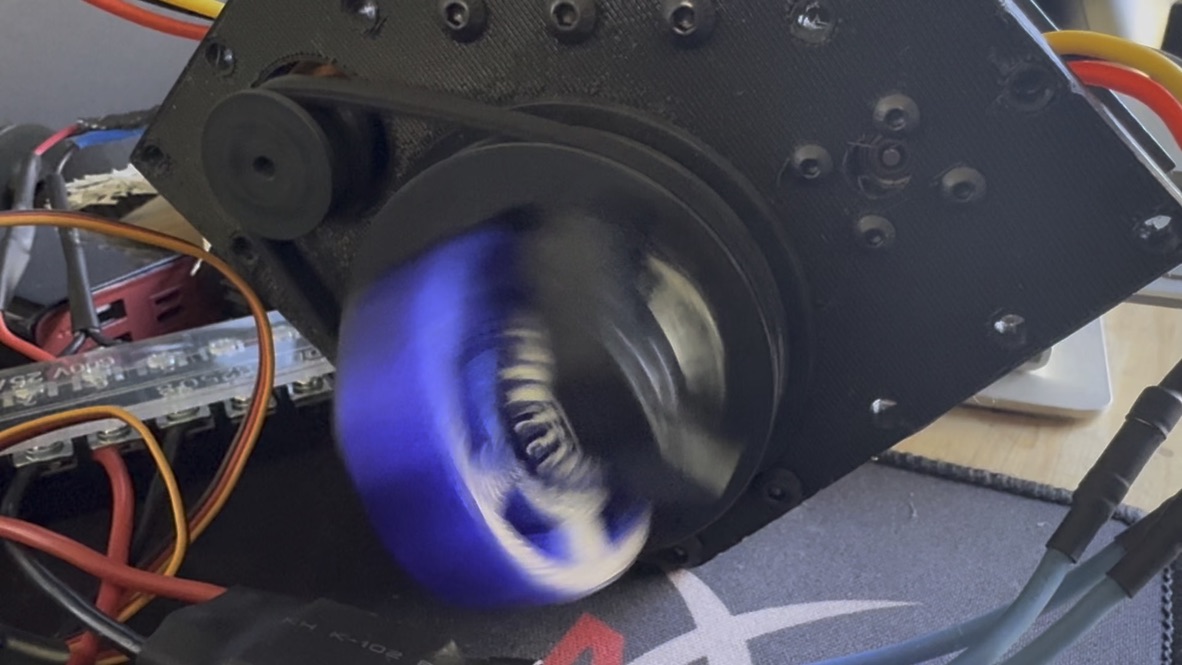

3D-Printed Swerve Module in action

Fully 3D-printed swerve drive module with BLDC motors

Problem & Goal

Traditional swerve modules rely on expensive, custom, or obscure parts. That barrier makes "trying swerve" unrealistic for many teams.

Goal: a printable, cheap, and vendor-accessible swerve that lowers the threshold for experimentation. Currently in early development and testing phases.

Design Approach

- Fully 3D-printed structure with commodity hardware; no machining

- Compact steering stage; printed gear/belt reductions

- Standard bearings and fasteners (Amazon sourcing)

- Module designed to be serviceable and hackable

Hardware

- Controller: Arduino (simple C/C++ firmware)

- Drive: Brushless DC motor + ESC

- Steer: BLDC or high-torque servo (variant)

- Wiring: Simple harness + power distribution; optional IMU for field-centric control

Control & Math

Starter swerve kinematics provided in the code:

- Convert desired chassis velocities

(vx, vy, ω)to module azimuth and wheel speeds - Optional field-centric transform using IMU heading

- Example PID for azimuth and speed with tuning notes

Starter Kit (for teams)

- Basic 3D CAD: STL/STEP + editable source

- Bill of Materials with Amazon links

- Wiring diagram and firmware template

- Build & calibration steps (azimuth zeroing, PID gains, wheel radius)

Cost & Accessibility

Focused on low cost via Amazon and common vendors. Per-module cost target kept intentionally low with upgrade paths for motors, bearings, and encoders.

Current Development Status

This project is currently in early development with active prototyping and testing. The design is being iterated based on initial testing results and community feedback. While the concept shows promise, it's important to note that this is still an experimental approach to swerve drive design.

Challenges

- Print durability & wear surfaces

- Backlash and tolerances in printed drivetrains

- Steering accuracy and sensor choice

- ESC tuning & current limits

What I Learned

Open-hardware stewardship, documentation as a product, rapid prototyping loops, and working on complex projects like this requires a strong foundational understanding of the math and kinematics behind it.

What's Next

Project has been shelved thus far, but pans to completely redesign the module with proper a plug and play code base to support beginners

Built With

Arduino · C++ · BLDC Motors · 3D Printing · CAD/CAM · Kinematics · PID Control